HUSQVARNA FE 501 2025

HUSQVARNA

| Performance: | Dimensions: |

| Engine Displacement: 510.9 cm³ - 1-cylinder, 4-stroke engine | Lean Angle: 63.9 ° |

| Peak Torque: 60 Nm | Stroke: 72 mm |

| Transmission: 6-speed | Seat Height: 952 mm |

| Power: 65 HP | Fuel Capacity: 8.0L |

| Front Suspension: WP XACT cartridge Ø 48 mm | Weight: 125 kg |

| Rear Suspension: WP XACT Monoshock with linkage | Front / Rear Brake Disc Diameter: 260mm /220 mm |

| Performance: | Dimensions: |

| Engine Displacement: 510.9 cm³ - 1-cylinder, 4-stroke engine | Lean Angle: 63.9 ° |

| Peak Torque: 60 Nm | Stroke: 72 mm |

| Transmission: 6-speed | Seat Height: 952 mm |

| Power: 65 HP | Fuel Capacity: 8.0L |

| Front Suspension: WP XACT cartridge Ø 48 mm | Weight: 125 kg |

| Rear Suspension: WP XACT Monoshock with linkage | Front / Rear Brake Disc Diameter: 260mm /220 mm |

01. PROGRESSIVE PERFORMANCE

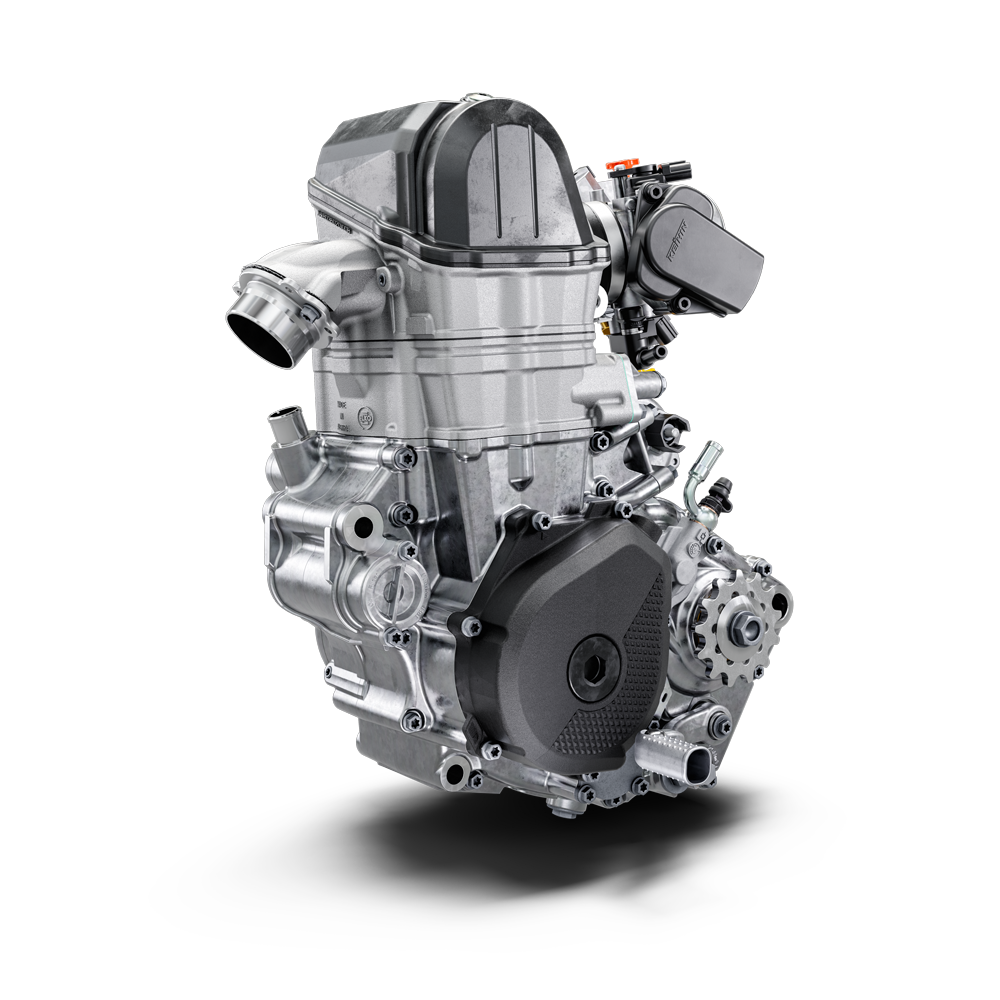

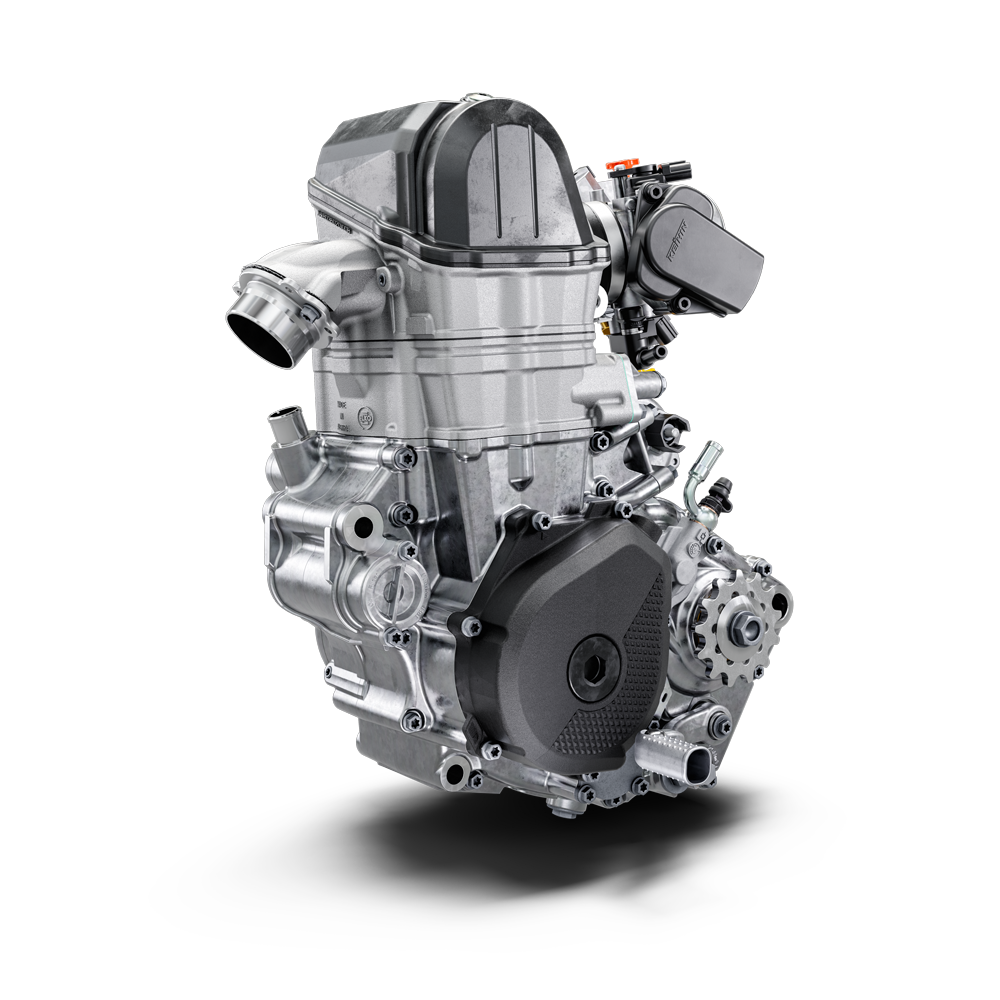

ENGINE

The FE 501 engine benefits from advanced engineering techniques to deliver maximum performance. The engine is tilted two degrees backwards for significantly improved anti-squat behavior from the chassis, which further aids the centralization of mass for exceptional overall handling. Servicing the FE 501 engine was a key focus during the design process with the addition of service markers on the engine cases to simplify maintenance. The 4-stroke engine produces a considerable amount of power making it the ideal dual-sport companion.

CYLINDER HEAD

The SOHC cylinder head is incredibly compact and lightweight with the camshaft positioned as close to the center of gravity as possible. A durable, fine-punched cam chain and Diamond-Like Carbon (DLC) coated rocker arm offer optimal efficiency and reliability with a single oil spray jet providing effective cooling. Valve timings are optimized for maximum torque and a smooth power delivery.

CYLINDER AND PISTON

The lightweight aluminum cylinder is an engineering masterpiece with a 95 mm bore and a stroke of 72 mm. Inside, the forged CP bridged-box-type piston features anodized annular grooves for added durability and extended service intervals. The compression ratio remains unchanged at 12.75:1.

CRANKCASES

Designed to be low in weight without sacrificing strength or reliability, the crankcases are made using a high-pressure die cast production process to create a thin-wall design. To centralize engine mass, the shaft arrangements are precisely positioned to harness rotating masses at the ideal center of gravity.

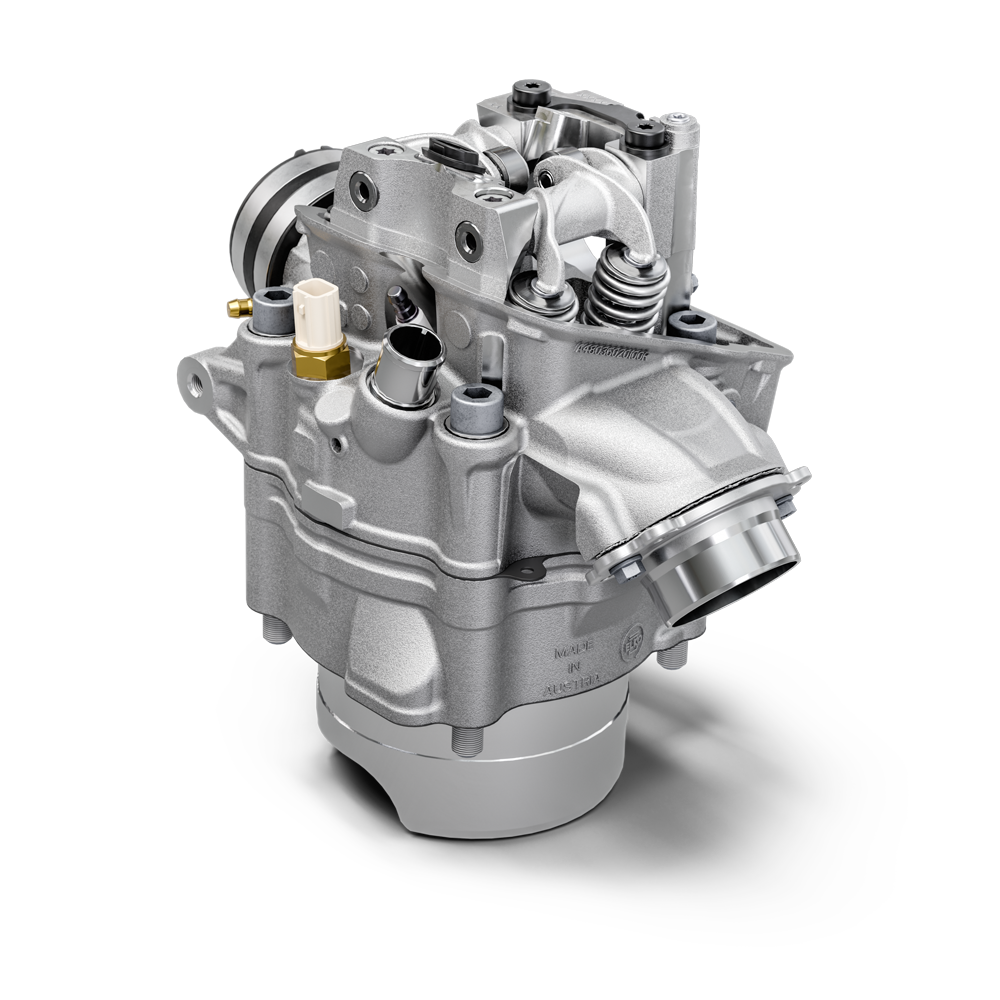

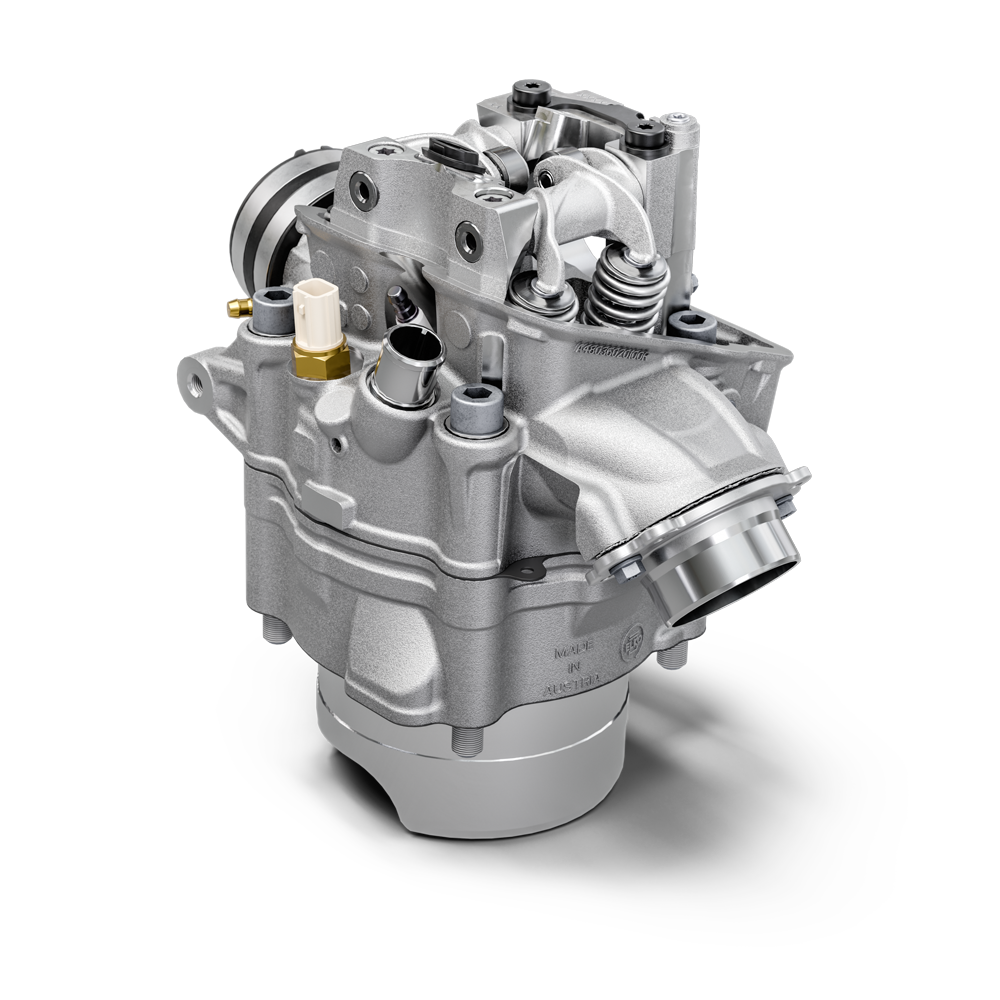

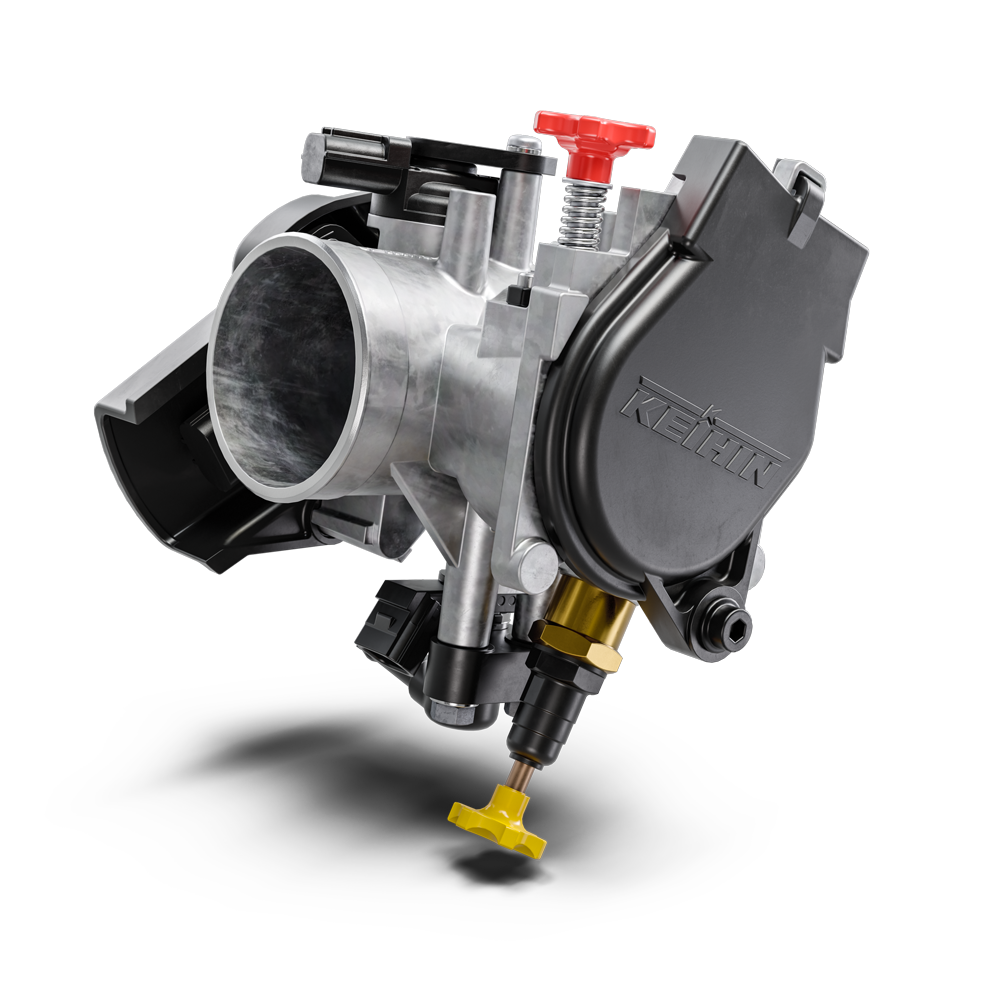

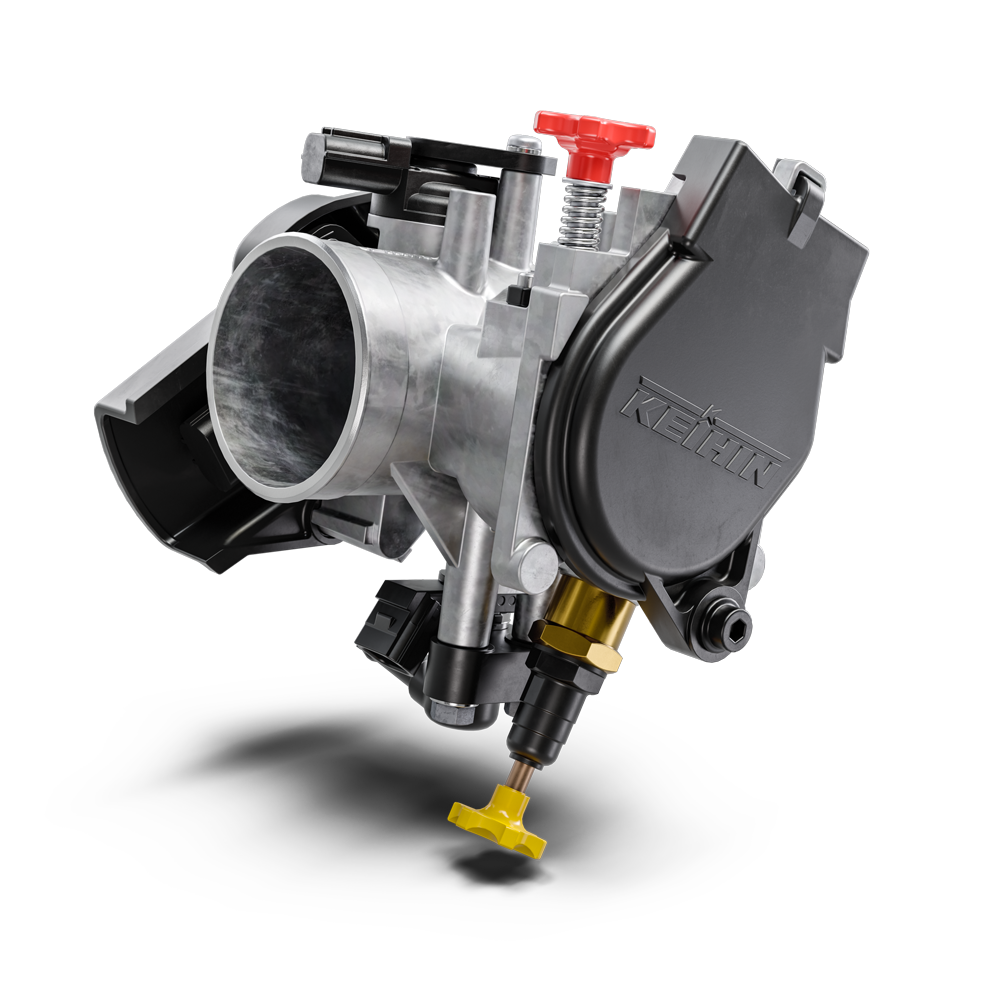

THROTTLE BODY

The FE 501 features a 42 mm Keihin throttle body optimized for throttle response. The injector is positioned to ensure the most efficient flow into the combustion chamber with the throttle cable mounted directly without a linkage for an enhanced response.

EXHAUST

The exhaust system is expertly designed to deliver class-leading performance at the lowest possible weight with the header pipe manufactured in two pieces. This design allows the header pipe to be removed without having to remove the rear shock. Further innovation allows for a short, compact silencer without increasing sound levels. The silencer is crafted from lightweight aluminum and stylishly finished with a black coating to highlight its premium quality.

02. STATE-OF-THE-ART CHASSIS

FRAME

A proven chromium molybdenum steel frame ensures straight-line stability at speed without sacrificing agility through the slow and technical sections. Optimized wall thickness throughout the chassis aids durability, in addition to providing unparalleled rider feedback and energy absorption. For an optimized level of anti-squat behavior and overall chassis balance, the shock is not directly connected to the main tube. The frame is complete with a premium metallic blue powder coating with frame protectors offering improved grip in all conditions.

HYBRID SUBFRAME

Made from 60% polyamide and 40% aluminum, the subframe offers exceptional strength and durability at a low overall weight of just 3.9 lb (1.8 kg). The lower subframe spars and frame mounts are manufactured from cast aluminum for reliability with the upper section made from injection-molded polyamide to enable specific flex characteristics.

SWINGARM

The swingarm is manufactured using a die-cast production process for optimal rigidity. To match the flex characteristics of the chassis, a 22 mm rear axle is utilized. Additionally, the swingarm is designed to enhance the durability of the chain glider while the chain guide features a rounded profile that makes it less prone to catching on external objects.

BODYWORK

Adorned with clean, Swedish-inspired graphics, the bodywork is designed to allow riders to perform at their best for extended periods of time. A flat seat profile offers unrestricted movement with a new, high grip cover ensuring riders stay firmly in place under hard acceleration. Above the side panels, recessed pockets allow for the machine to be lifted and moved, which is particularly beneficial in highly technical terrain.

RADIATORS

Manufactured from high-strength aluminum, the radiators are designed using Computational Fluid Dynamics (CFD) to channel air through them in the most effective way. A large center tube channels coolant through the frame to reduce pressure at this point in the system for a more consistent flow. An internal thermostat enhances reliability while the radiator cap features a bayonet style closure for a secure fitment.

TRIPLE CLAMPS

The black-anodized, CNC-machined triple clamps offer premium quality as standard. They have a carefully calculated 22 mm offset and are expertly crafted using superior techniques and materials for the highest levels of quality and reliability. The handlebar clamp has a large contact surface with the ProTaper bars to help prevent twisting in the event of an impact and offers two mounting options for customizable ergonomics.

03.INNOVATIVE ADVANTAGE

WP XACT FRONT FORKS

Designed and developed for the rigors of enduro riding, the WP XACT Closed Cartridge spring forks offer consistent performance thanks to an innovative internal design that optimizes oil flow and prevents oil from foaming. The hydrostop, effective in the last 68 mm of travel, is highly advantageous when landing heavily as it helps to maintain forward momentum. Additionally, riders can alter the compression and rebound settings quickly and easily using the tool-free adjusters found at the top and bottom of each fork leg..

WR XACT REAR SHOCK

The lightweight WP XACT rear shock offers 300 mm of travel. With the rebound and both high and low speed compression adjustable by hand, setting changes can be achieved quickly and easily without tools. Complete with a CFD optimized shock piston, low friction seals, and a new, smaller linkage bolt to reduce weight, consistent damping, comfort, and traction is guaranteed.

HYDRAULIC BRAKES

The highest level of performance is guaranteed thanks to the class leading Brembo calipers and controls, which are new for 2025. Together with GSK wave discs (260 mm disc front and 220 mm rear), which are designed to prevent mud from building up, superior stopping power and braking confidence is assured in all conditions.

HYDRAULIC CLUTCH

The new, high-performance Brembo hydraulic clutch system delivers even wear, near maintenance-free operation, and perfect feel in every condition. With this hydraulic system, free play is constantly compensated so that the pressure point, and the function of the clutch, remain identical in cold or hot conditions, as well as over time. Countless hours of testing have proven the reliability of the high-quality, Italian-made Brembo hydraulic system.

WHEELS AND TIRES

Black high-strength alloy rims by D.I.D are laced to CNC machined hubs using lightweight spokes and silver anodized aluminum nipples. Fitted to the wheels are Continental TKC 80 dual-sport tires, which offer superior grip on a wide variety of terrain.

04. TECHNOLOGY ADVANCED

LED HEADLIGHT

The LED headlight provides a remarkably bright light output for excellent visibility at night and is particularly effective when riding through dense woodland. A clever mounting design sees the LED lighting unit fitted inside the headlight mask using a quick-release system that allows it to be replaced quickly and easily if damaged.

OFFROAD CONTROL UNIT

The OCU replaces electronic fuses and relays (main relay, fan relay, light relay) and can be found under the seat. All outputs are switched depending on signals from the voltage regulator and the ECU. In the event of over-current, outputs are deactivated individually. This allows a simple error detection as the status of each output is indicated by an LED light, making it easy to find an issue quickly and get back to riding.

THROTTLE AND GRIPS

The ODI lock-on grip on the left side does not require gluing, while on the right, the vulcanized grip features an innovative integrated throttle mechanism. The assembly has easy free-play adjustment and, by changing a cam, throttle progression can be altered. The throttle housing has been designed for optimal stability and resistance against impacts.

ELECTRIC START

Taken from the motocross range, the combined start/stop switch is located on the right side of the handlebar for easy, thumb-operated use. Not only simplifying the starting and stopping of the engine, but the removal of a designated stop only button from the handlebar reduces the risk of potential damage or activation in the event of a fall.

FOOTREST

Using state-of-the-art computational fluid dynamics, the large footrests are designed for maximum control and to prevent mud from building up. Additionally, the mounting position brings them inwards, which makes them less susceptible to catching on the ground through deep ruts.

AIRBOX

With precisely positioned inlet ducts reducing air flow deformation, the airbox ensures unrestricted airflow with maximum filter protection. The Twin Air filter is mounted onto a cage designed to offer accurate installation and can be easily accessed without tools by removing the left side panel.

|

ENGINE

|

CHASSIS

|